Chemical Pumps

General

- Non clogging tendency

- Handle light slurries

- Without problems

- Micrometric wear adjustable facility hence

- Worries at constant head for longer period

- Grease/Oil lubricated bearing

- Dynamically balanced impeller

- Less noise

- No vibration

- Centre delivery

- No Air locking

Applications

- Organic/Inorganic Chemical

- Steel Industries

- Fertilizers

- Ceramics

- Dyes

- Kerosene

- Pulp And Paper , Textile

- Food Industries etc…

Operating Range

- Capacity – Q- Up To 80 M3/Hr.

- TDH H – Up To 62 Mtr.

- Pump Sizes – DN 25 mm To 50 mm

- Speed – N – 1440/2880 rpm at 50 Hz and 1750/3500 rpm at 60 Hz

- Temperature 110 C

Material of Construction

- Cast Iron

- SS-304

- SS-316

- SS-316L(cf3m)

- Bronze

- Carbon Steel (WCB)

- SS304L (CF3)

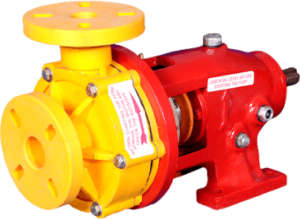

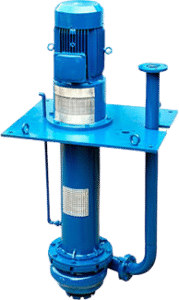

Polypropylene Pumps

Applications

- Effluent Treatment

- Water Treatment Plants

- Drugs And Pharmaceuticals

- Fertilizer Plants

- Plants

- Thermal And Atomic Power Plants

- Pharmaceutical Industry etc…

Operating Range

- Capacity – Q- Up To 100 M3/Hr.

- TDH H – Up To 55 Mtr.

- Pump Sizes – DN 25 mm To 100 mm

- Speed – N – 1440/2880 rpm at 50 Hz and 1750/3500 rpm at 60 Hz

- Temperature 80 C – 140C

Material of Construction

- PP/PVDF/UHMWP

Optional Accessories

- M.S. Fabricated Base Frame

- Flexible Coupling

- Coupling Guard

- Foundation Bolt.

Monoblock

Applications

- Industrial Application

- Water Boosting

- Suitable For Water Supply Scheme

- Commercial Complexes

Applications

General Irrigation And Sprinkler Irrigation

Air Conditioning

Hotels

Cooling Tower

Operating Range

- Capacity – Q- Up To 120 M3/Hr.

- TDH H – Up To 60 Mtr.

- Pump Sizes – DN 25 mm To 100 mm

- Speed – N – 1450/2900 rpm

- Temperature up to 80 C for P.P. & other M.O.C. up to 250 C

Material of Construction

- Graded Grey Cast Iron

- S.S.316, 304

- Polypropylene

- All Wetted Parts Of Cast Iron /Gun Metal/SS-316/ Polypropylene

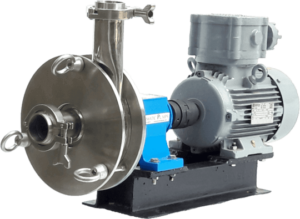

Dairy Pump

This Pumps are Designed to meet the hygienic requirements of the dairy, food and beverage, and personal care industries, Dairy Pumps standardized centrifugal pump for general applications, intermittent product pumping and CIP duties.

- Solid value

- Solid hygienic design

- Easy, low-cost maintenance

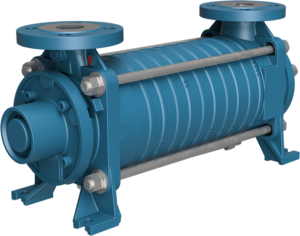

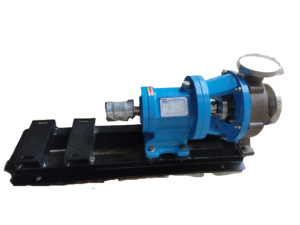

Centrifugal Pumps

General

- Horizontal

- Foot mounted

- Single stage

- End suction and top centerline discharge confirming to DIN 24256/ISO 2858 standards and in general confirming to API 610 as well.

Applications

- Chemical Process Industries

- Fertilizer Plants

- Bulk Drugs And Pharmaceutical

- Heating And Air Conditioning Plants

- Sugar Plant

- Water Supply

- Pulp And Paper , Textile

- Cement, Agriculture

- Jet Dyeing

- Hot Water etc

Operating Range

- Capacity – Q- Up To 1100 M3/Hr.

- TDH H – Up To 150 Mtr.

- Pump Sizes – DN 25 mm to 300 mm.

- Speed – N – 960/1450/2900rpm at 50 Hz and 1150/1750/3500 rpm at 60Hz

- Temperature 350 C

Material of Construction

- Graded Grey Cast Iron

- Alloy Steel

- CF8M

- CF3M(SS-316l)

- CD4MCU

- Ni-Resist

- R55

- Gun Metal/Bronze

Material of Construction

- Carbon Steel ( WCB)

- CF8

- CF3

- Alloy 20

- Nickle and Ni-Alloys

- 2-1nicl

- Hastelloy- B/C

Boiler Feed Self Priming Pump

Applications

- Boiler Feeding

- Power Plant , Cooling Towers

- Edible Castor Oil Circulation Of Lubrication Oils

- High Pressure Testing

- High Head Delivery Condensate Recovery

Operating Range

- Capacity – Q- Up To 20 M3/Hr.

- TDH H – Up To 250 Mtr.

- Pump Sizes – DN 15 mm To 50 mm

- Speed – N – 1450 rpm at 50Hz and 1750 rpm at 60 Hz

- Temperature 90 C

- Pressure 26 bar.

Material of Construction

- Cast Iron

- SS-316

- SS-304

- Bronze

Optional Accessories

- M.S. Fabricated Base Frame

- Flexible Coupling

- Coupling Guard

- Foundation Bolt.

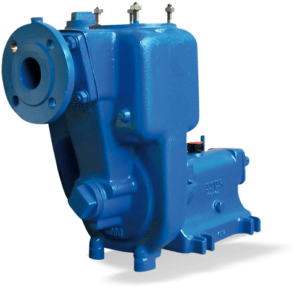

Self Priming Pumps

Applications

- Effluent and sewage treatment plant

- Petroleum product handling

- Incinerator

- Agriculture Purpose

- Dewatering Purpose

- Swimming Pools

- Loading And Transfer Of Oils

- Ceramic

- Re-rolling Mills

- Pits

- Rain And Storm Water

Applications

- Thermal Plant

- Steel Plant

- Slurry Material Handling

- Mud

- Marine

- Hotel

- Spirits

- Filter Press

- Trenches

- Construction Sites

- Chemicals etc…

Operating Range

- Capacity – Q- Up To 650 M3/Hr.

- TDH H – Up To 50 Mtr.

- Pump Sizes – DN 40 mm To 200 mm

- Speed – N – 1440/2880 rpm at 50 Hz and 1750/3500 rpm at 60 Hz

- Temperature 110 C

Material of Construction

- Cast Iron

- Alloy Steel

- Carbon Steel (WCB )

- CF8 , CF8m

Optional Accessories

- M.S. Fabricated Base Frame

- Flexible Coupling

- Coupling Guard

- Foundation Bolt.

Heavy Duty Pump

Applications

- Acids

- Alkalies

- Hydrocarbons

- Chemical effluents

- Water supply

- Abrasive slurries

- Solvents

- Seawater

- Condensates

- Heavy chemicals

User Industries

- Acid plants

- Refineries

- Effluent treatment

- Extraction plants

- Petrochemicals

- Desalination

- Fertiliser plants

- Pharmaceuticals & bulk drugs

- Paints & dyes

- Sugar

- Steel

- Mining

Operating range

- Flow capacity: upto 2,000 m3 /hr

- Head: upto 150 m.l.c.

- Delivery size: 25 mm to 350 mm

- Temperature: -30oC to 160o (upto 450oC for ‘S’ type execution)

- Design pressure: upto 16 kg/cm2

- Specific gravity: upto 1.90

- Viscosity: 20 cSt (higher viscosity handling on request)

- Speed: 960 / 1450 / 2900 rpm

- Solids passage (mm): Not intended

Material Combinations

- Cast iron, ductile iron, alloy cast iron

- Plain carbon steels

- Stainless steels

- Duplex & super duplex stainless steels

- Super alloys

- Nickel alloys

- Ni resist

- Copper alloys

- Titanium

- Rubber lined

Optional features

- Variety of wear rings

- Oil lubricated bearings

- Water cooled coil chamber for high temperature application oil lubricated bearings

- Provision for all API flushing plans

- Flange drilling as per ANSI / IS standards

- Shaft sealing by gland packing or variety of mechanical seals

Teflon Lined Pump

Material of Consturction

- LINING : PFA-(Teflon)

- FEP-(Teflon)

- PVDF

Applications and Industries Served

- Chemical processing

- Drugs and Pharmaceuticals

- Petrochemicals

- Effluent Treatment

- Food processing

- Fumes scrubbing

- Agro chemicals

- Tanneries

- Perfumeries

- Detergents and caustics

- Breweries

- Acid pickling

- Dyes and pigments

- Tanneries

- Paper and Pulp industries

- Photographic processing

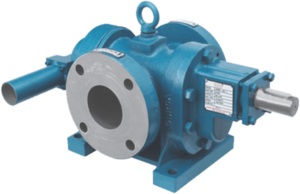

Rotary Gear Pumps

Applications

- L.D.O.

- Hot Grease And Tallow

- F.O.

- Syrups

- Glueplant

- Thermic Fluid

- Liquors

- Milk

- Bitumen

- Resins And Pigments

Applications

- Highly Viscouse Or Semi Viscouse Liquids

- Soap Spary Mixturte

- Soft Drinks

- Tar

- Glycerine

- Food Industries

- Kerosene

- Dyes

- Paper Pulp

- Chemical Plants etc…

Operating Range

- Capacity – Q- Up To 125 M3/Hr.

- TDH H – Up To 17 Kg/Cm2.

- Pump Sizes – DN 2 mm To 150 mm

- Viscosity 100000 CST

- Speed – N – Max. Speed In 1440 rpm Reduction As A Function Of Viscosity

- Temperature 110 C

Material of Construction

- Cast Iron

- Gun Metal

- SS-316

- Cast Steel ( WCB)

- SS-304

- Alloy- 20

Optional Accessories

- M.S. Fabricated Base Frame

- Flexible Coupling

- Coupling Guard

- Foundation Bolt.