Pusher Seals

Standard Style

- Face Materials: Stellite, Carbon, Ceramic, Tungsten Carbide, Silicon Carbide, Lecrolloy

- Metal Parts: SS 316, SS 304

- Secondary Seal: Elastomers, PTFE

Applications

- Water Pumps

- Circulation Pumps for central heating

- Chemical Process Pumps

- Sewage and Submersible pumps

Seal Characteristics

- Single acting

- Unbalanced

- Inside mounted

- Dependent of direction of rotation

Operating Limits

- Shaft Diameter d1 : 10 mm to 100 mm

- Pressure p : 08 bar (max)

- Temperature t : -20°C to +200°C

- Velocity v : 20 m/sec

Single Spring Seal

Standard Style

- Face Materials: Carbon/Stellite / Lecrolloy / Ceramic / Silicon Carbide / Plasma Sprayed Ceramic

- Metal Parts: SS 316, SS 304

- Secondary Seal: Nitrile, EPDM, Viton, PTFE

Applications

- Industrial

- Marine

Seal Characteristics

- Single acting

- Balanced / Unbalanced

- Inside & Outside Mounted

- Independent of direction of rotation

- Torque Transmission by Secondary seal

Operating Limits

- Shaft Diameter d1 : 10 … 100 mm

- Pressure p : 10 bar (max)

- Temperature t : – 20 … +180O C

- Velocity v : 10 m/sec>

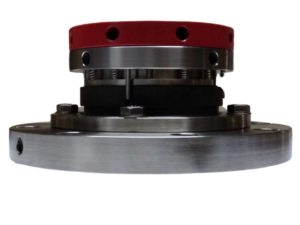

Multi Spring Seal

Features

- Directly slip-on type hydraulically balanced seal design

- Revolutionary concepts in design engineering

- Near-universal applicability interchangeability with nearly all conventional seals and gland packings without pump or gland modification

- No seal induced shaft damages saves hidden maintenance costs for shaft/ sleeve repair/renewal

- Lower price than conventional seals because of high degree of standardization

- Uniform installation dimension for all sizes results in ease of handling

Application Data of seal type 707

- Seal faces: Carbon, Stellite, Plasma Sprayed Ceramic, Tungesten Carbide, Silicon Caribide

- Elastomer: EPDM , Neoperene ,Viton, TEV, Kalrez

- Size range: 16 to 150mm

- Pressure: 35 bar

- Temperature: 205°c

Application Data of seal type 808

- Seal faces: Carbon, Stellite, Plasma sprayed ceramic, Tungesten carbide, Silicon caribide

- Elastomer: Viton®, Neoperene, Kalrez®, EPDM, TEV

- Size range: 108mm to 150mm

- Pressure: 35 bar

- Temperature: 205°c

Applications

- Industrial

- Marine

Textile Seal

To Be Use For

- Caustic

- Acidic

- Sodium Hydrogen Carbonate

Operating Limits

- Shaft Diameter : As per machine required

- Pressure : Normal

- Temperature : Normal

Material Of Construction

- Sealing faces : Carbon, Silicon Carbide, Tungsten Carbide, Chrome Cast Steel & which are suitable for fluid

- Elastomer :Viton, EPDM, Silicon, Aflas, PTFE, Hypalon

- Hardware : SS 316, Hastelloy C, Monel, Alloy 20

Part Of Identification

- Rotary Face (Seal Ring)

- Stationary Face (Mating Ring)

- Elastomer

- Spring

- Other Hardwere

Teflon Bellow Seals

Standard Style

- Face Materials: GFT / CFT / Silicon Carbide / Ceramic

- Metal Parts: SS 316, SS 304, Hastelloy-C

- Springs: Teflon Covered Spring Steel, S.S.316 , S.S.304 , Hastelloy-C

- Secondary Seal: PTFE Bellows

Applications

- Extremely corrosive services

Seal Characteristics

- Single acting

- Outside mounted

- Multi Spring & Single Spring Design

- Independent of direction of rotation

Operating Limits

- Shaft Diameter d1 : 19mm to 150mm

- Pressure p : 6 bar (max)

- Temperature t : -45 ….+1200C

- Velocity v : 16 m/sec

Metal Bellow Mechanical

Materials

- Faces : Carbon, Silicon Carbide, Tungsten Carbide.

- Elastomers : Graphite, Perflouro, FEP.

- Hardware : SS-316, AM-350, Hastelloy-C, Alloy-20

Operating

- Pressure : 25 bar

- Temperature : -40°C to 350°C

- Speed : 20 m/s

- Sizes : 25 mm to 100 mm

Application

- High Temperature, Hydrocarbons & Critical Services

Boiler Feed Water Seals

Standard Style

- Face Materials: Carbon/ Ceramic / Silicon Carbide / Tungsten Carbide

- Metal Parts: SS 316, SS 304

- Secondary Seal: Elastomers

Applications

- Boiler feed water Pumps

- HSD Pumps

- Booster Pumps

- Drip Pumps

- Condensate Pumps

- Fuel Oil Pumps

Seal Characteristics

- Single acting

- Balanced

- Inside mounted

- Dependent of direction of rotation

Operating Limits

- Shaft Diameter d : 65 … 150 mm

- Pressure p : 50 … 140 bar (max)

- Temperature t : – 20 … +250O C (API plan 23)

- Velocity v : more then 50 m/sec

Split Seals

Standard Style

- Face Materials: Carbon / Silicon Carbide / Ceramic

- Metal Parts: SS 316, SS 304

- Secondary Seal: Elastomers

Applications

- Utility Pumps

- Transfer Pumps

- Agitator and Vessels (As Dry Running Seal)

Seal Characteristics

- Fully Split Components

- Ease of Installation

- Balanced Seal Faces

Operating Limits

- Shaft Diameter d : 50….200 mm

- Pressure p : 15 bar (max)

- Temperature t : Amb…. 1400 C

- Shaft speed : 3600 rpm (max)

High Pressure Seal

Standard Style

- Face Materials: Carbon / Silicon Carbide / Tungsten Carbide

- Metal Parts: SS 316, SS 304, Hastelloy-C,Titanium, Alloy-20, Monel

- Secondary Seal: Elastomers

Applications

- Oil Pipeline Pumps

- Boiler Feed Water Pumps

Seal Characteristics

- Single acting

- Balanced

- Inside Mounted

- Independent of direction of rotation

- Multiple springs design

- Sturdy drive mechanism

Operating Limits

- Shaft diameter d1 : 25…..115 mm

- Pressure p : 25….150 bar

- Temperature t : _ 40…..1800 C

- Velocity v : 20 m/sec

Dry Seals

Materials

- Housing: Stainless steel

- Product-wetted parts: Stainless steel, Hastelloy, Titanium, special materials

- Seal rings: Carbon, Silicon Carbide, Tungsten Carbide, etc

- O-rings: Viton, EPDM, Perfluor elastomers, special elastic materials

- FDA-approval: Possible for all product-wetted parts

Application

- Flue gas desulfurization (FGD)

- Hydrometallurgy

- Pharmacy

- Biotechnology

Application Limits

- Vessel pressure: Vacuum …16 bar (abs.)

- Vessel temperature:-50 … +200° C

- Shaft size: 40 … 300 mm

- Sliding speed: 5 m/s

Cartridge Single Acting

Standard Style

- Face Materials: Tungsten carbide and ceramic, secondary seal

- Metal Parts: SS 316, SS 304, Hastelloy – C, Hastelloy – B, Monel, Alloy – 20

- Secondary Seal: Elastomers, TCV,PTFE

Applications

- Food Products

- Pharmaceutical Products

Seal Characteristics

- Single acting

- Reverse Balanced

- Outside Mounted

- Independent of Direction of rotation

- Dry Running

Operating Limits

- Shaft Diameter d : 15 …150mm*

- Pressure p : Vacuum …. 8 bar (max)

- Temperature t : Amb. …. 120O C (max)

- Speed n : 320 rpm

Cartridge Double Acting

Standard Style

- Face Materials: Carbon , Ceramic, Silicon Carbide, Tungsten Carbide, Lecrolloy

- Metal Parts: SS 316, SS 304, Carbon Steel, Hastelloy-B,Hastelloy-C, Monel, Alloy – 20

- Secondary Seal: Inboard – PTFE, GFT : Outboard – Elastomers

Applications

- Petrochemicals and its vapours

- General Chemicals and its vapours

- Light hydrocarbons and its vapours

Seal Characteristics

- Double acting Back to Back Seals

- Balanced

- Cartridge Unit

- Independent of Direction of Rotation

- Operated with Pressurised Barrier Fluid

Operating Limits

- Shaft Diameter d : 25 …..150mm*

- Pressure p : Vacuum …. 35 bar (max)

- Temperature t : Amb. … 2000c (max)

- Shaft speed n : 600 rpm. (max)

- Barrier fluid pressure : Vessel pressure + 1.5 bar

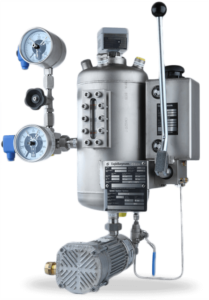

Thermosyphon Vessel

Performance Limits

- Capacity : 7.5 Liter

- Hyd. Test Pressure : 30 Kg

- Working Pressure : 20 Kg

- Max. working temp.: 180°C

- Heat Transfer area of cooling coil : 0.3m²

- Cooling water flow rate

Metal Parts

- Thermosyphon Shell : Carbon Steel / SS 316/SS304

- Cooling Coil: SS 304 / SS 316>

Recommended: 12 Ltrs /min

Max. Level Value : 5.5 Ltrs

Min. Level Value : 3.5 Ltrs

Accessories

- Pressure Gauge (0- 40 kg/c m²)

- For Pressure Measuring of the vessel

- Level Gauge For Liquid Level Indicate of the vessel

- Hand Pump For recharge of the vessel With additional quantity of barrier fluid when Thermosyphon is under pressure and Liquid level is low.

Connection Size

- Buffer fluid Inlet – A ½” NPT

- Buffer fluid Outlet – B ½ NPT

- Cooling water Inlet – C ½” NPT

- Cooling water Outlet – D ½” NPT

- Hand Pump Connection – E – ¼: NPT (Refilling Connection)

- Filling Connection – F –1 ¼” NPT

- Pressure Gas Connection – G ½” NPT

- Pressure Gauge Connection – H 3/8″ NPT

- Drain – I ½” NPT

- Safety Valve Connection – J ½” NPT